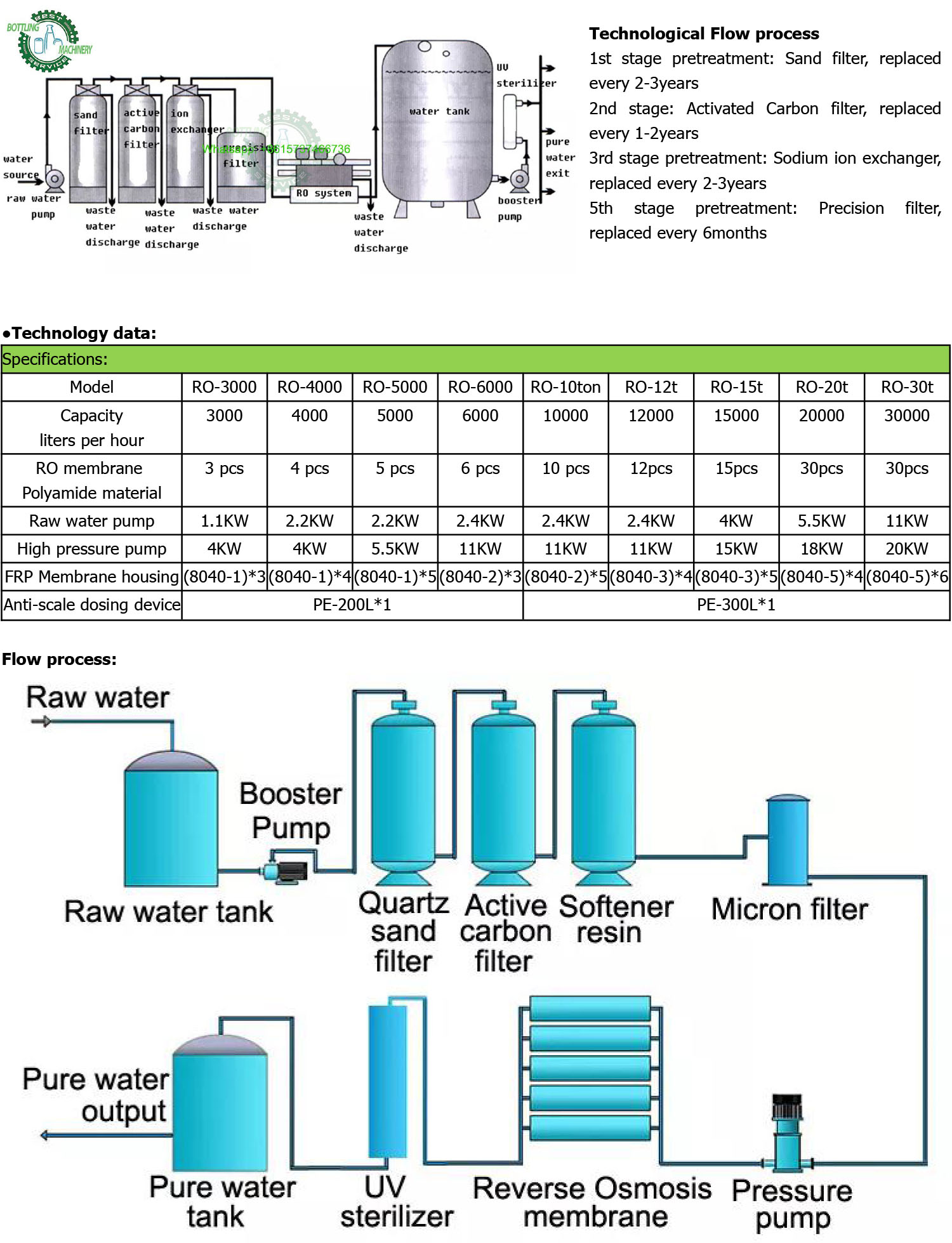

Description of 12000LPH 12ton/hour 12m3/h RO reverse osmosis water treatment machinery:

Reverse osmosis equipment is composed of pretreatment system, fine treatment system and post-treatment system. After the raw water is pretreated by PP filter element (sand bar filter), activated carbon unit, water softener unit and other pretreatment systems, the content of suspended solids (particulate matter), colloid, organic matter, hardness, microorganisms and other impurities in the water is greatly reduced, so as to reduce the processing load of subsequent reverse osmosis, electric desalting and other fine treatment systems and prolong their service life.

Essential information of water treatment machinery:

Material: Polypropylene hot melt fiber filter element.

Characteristics: 10 μ M filter hole can intercept particulate matter in water (such as sediment and rust often found in tap water) and reduce turbidity, but it cannot filter bacteria and ionic substances.

Specification: 10 inch (250 mm) /20 inch (500 mm).

Activated carbon unit of water treatment machinery:

The specific surface area of activated carbon is very large, and it is full of micropores with very small pore size (10 ~ 30 angstroms), which has obvious adsorption and filtration effect on organic colloids, residual chlorine, iron ions, etc. 10 inch /20 inch activated carbon filter elements are commonly used in desktop water purifiers and water purifiers. Activated carbon filter tanks made of glass fiber reinforced plastic / stainless steel are commonly used in large pure water units.

Water softener unit of water treatment machinery:

Large and medium-sized pure water systems often use automatic softeners to remove calcium and magnesium ions from raw water. The full-automatic water softener is composed of sodium ion resin tank, regeneration salt tank and multi-channel control valve. It can set program control operation and automatic regeneration (time type / flow type). During regeneration, the siphon principle is used to absorb salt, and then water is injected to melt salt. The regeneration time is usually 2 hours.

Small desktop pure water machines generally use 10 inch /20 inch soft water resin filter elements to reduce the hardness of raw water.

Reverse osmosis unit of water purification equipment:

Ro (reverse osmosis) reverse osmosis technology is a membrane separation and filtration technology powered by pressure gauge difference. It originated from the research of Aerospace Science and technology in the United States in the 1960s, and has gradually been transformed into civil use. At present, it has been applied to scientific research, medicine, food, beverage, seawater desalination and other fields.

The pore size of RO reverse osmosis membrane is as small as nanometer (1 nanometer =10-9 meters). Under certain pressure, H2O molecules can pass through RO membrane, while inorganic salts, heavy metal ions, organics, colloids, bacteria, viruses and other impurities in source water cannot pass through RO membrane, so that permeable pure water and impermeable concentrated water can be strictly distinguished.

The removal rate of ion, colloid, bacteria and organic substances (including heat source) with molecular weight greater than 300 Dalton by RO membrane is more than 99%, and the removal rate of ion (na+, k+) is 95%. When the conductivity of source water is <3505µ S/cm, RO pure water conductivity is generally ≤ 55µ S/cm, in line with water standard. After circulating filtration by atomic ion exchange column, the water yield can reach 18.2m Ω cm。

Reverse osmosis is an economic method that can achieve 90% – 99% impurity removal rate, and it is also a pretreatment method of reagent grade ultra pure water system.

remarks

The filtration capacity of RO membrane is greatly affected by the water temperature. The suitable water temperature is 25 ℃ ~ 30 ℃, the temperature decreases by 1 ℃, and the water production of RO membrane decreases by about 3%. When the water temperature is close to 0 ℃, the RO membrane will stop producing water.

UV meter unit of water purifier equipment:

When a sufficient amount of strong ultraviolet light generated by the ultraviolet equipment irradiates water, liquid or air, various bacteria, viruses, microorganisms, parasites or other pathogens in it will be damaged by ultraviolet UV-C radiation, so as to prevent the regeneration of daughter cells. The ultraviolet disinfection equipment will kill the bacteria in water in a short time (usually 0.2-5 seconds) without using any chemical agents More than 99.9% of bacteria and viruses in liquid or air.